Name: The Rectifier, the High-frequency power supply

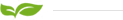

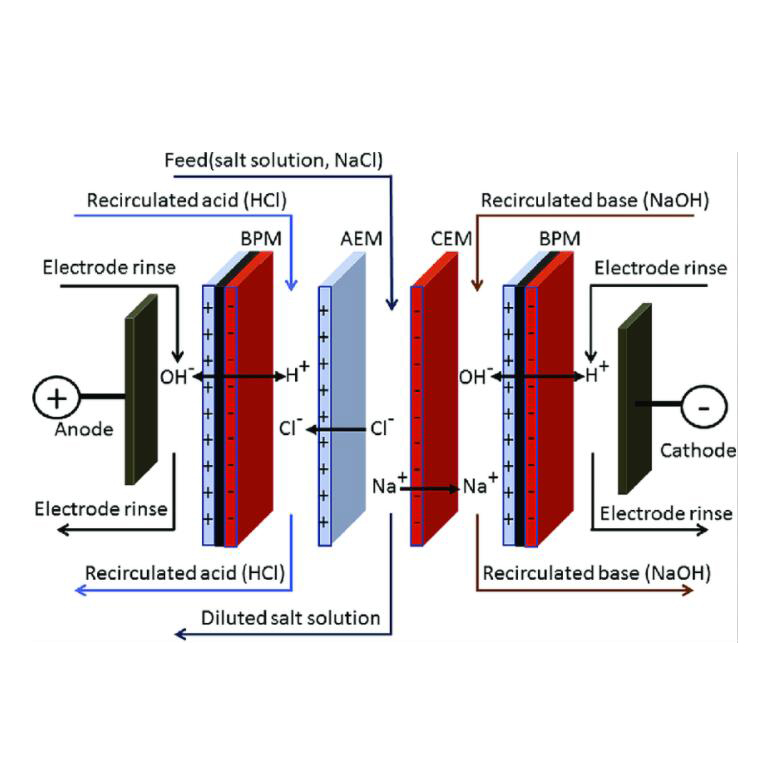

Principle of electrodialysis

Semiconductor PN junction has high current in forward bias and low current in reverse bias. Rectifier diode is a kind of PN junction diode that uses this unidirectional conduction characteristic of PN junction to change AC current into DC. Devices with a current capacity below 1 amp are usually called rectifier diodes, and those with a current capacity above 1 amp are called rectifiers.

Synonyms:The Rectifier, the High-frequency power supply

Application:This series of products are mainly used in metallurgy, chemical industry, copper foil, silicon carbide, chloric acid Potassium, electrolytic water hydrogen production, electroplating, electrolytic polishing, anodizing and other industries.

Rectifiers are widely used in various forms of rectified power supplies. The high-power rectifier power supply requires the rectifier to have a large current capacity, high breakdown voltage and good heat dissipation performance, but the junction area and junction capacitance of this device are large, so the operating frequency is very low, generally below tens of KHZ. Silicon material has large bandgap and good thermal conductivity, which is suitable for making high-power rectifier devices. In the high-voltage rectifier device often used high-voltage silicon stack, it is composed of a plurality of rectifier device core in series, the reverse voltage is determined by the pressure resistance of the tube core and the number of series tubes, the maximum voltage can reach hundreds of kV. If the high-frequency rectifier circuit is used at very high frequencies, when the AC voltage period is equivalent to the recovery time of the rectifier from the on state to the off state, the rectifier will no longer act as a rectifier for the high-frequency voltage. In order to meet the needs of high frequency operation, the method of gold doping is usually used in silicon rectifier to shorten the life of injected few carriers, so as to reduce the purpose of recovery time.

Month Capacity:300 pieces

The advantage of our rectificer:

1. The cabinet adopts a fully enclosed design, which is dust-proof, anti-corrosion, and prolongs its service life.

2. Ultra-high capacity margin, design of all key components> 3 times margin.

3. A water immersion electrode is arranged at the bottom of the rectifier cabinet to send out an alarm signal when water leakage occurs, which is convenient for maintenance

4. The thyristor is connected in series with a fast fuse to protect the components from damage.

5. Use RC and varistor to effectively prevent commutation and operating over-voltage.

6. Microcomputer dual-control hot standby system, automatic switching without disturbance.

7. The cabinet frame adopts non-magnetic rigid or aluminum alloy structure to cut off the magnetic circuit to reduce eddy current loss and prevent the cabinet from heating.

Applications Areas:

Electrolysis

Electrodialysis

Metallurgy,

Chemical industry,

Copper foil,

Silicon carbide,

Chloric acid Potassium,

Electrolytic water hydrogen production,

Electroplating,

Electrolytic polishing,

Anodizing and other industries.