About

Perfluorosulfonic Acid Ion Exchange Membrane for Hydrogen Production From Water Electrolysis

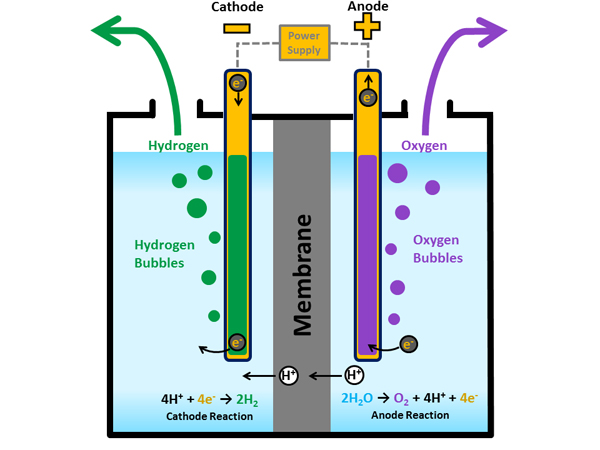

Perfluorosulfonic acid ion exchange membrane, also known as perfluorosulfonic acid proton exchange membrane and cation exchange membrane, is a solid polymer electrolyte, a strong acid type ion exchange membrane, with good chemical and thermal stability, low voltage, and low membrane resistance.

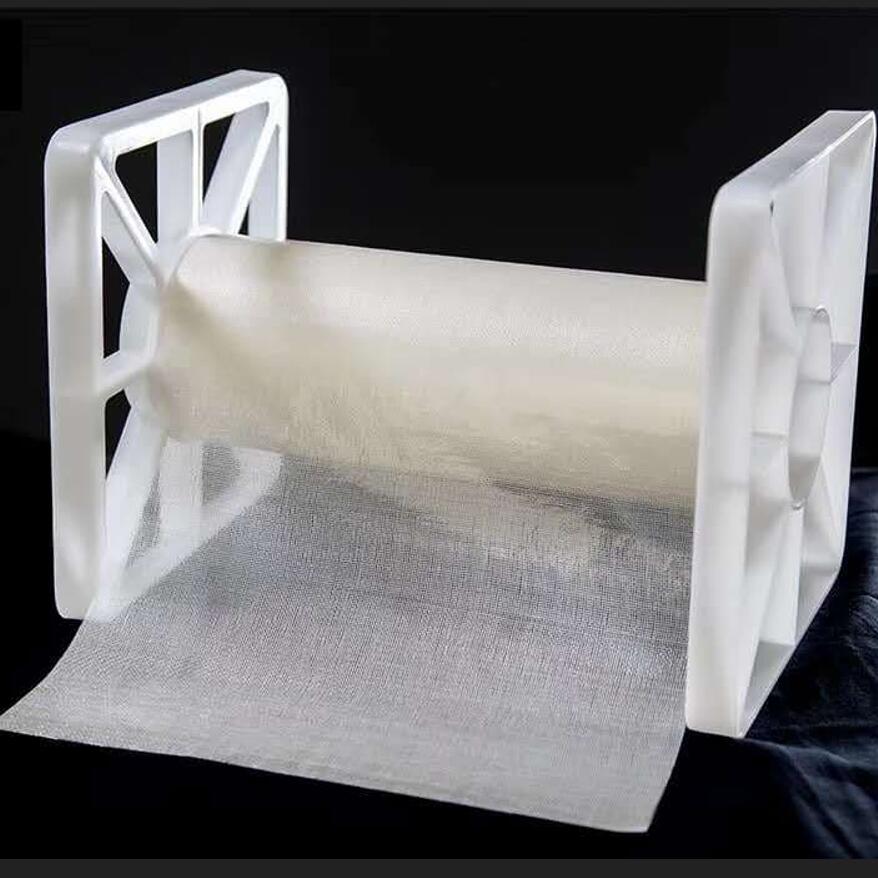

PEM proton membrane water electrolysis hydrogen production selects perfluorosulfonic acid proton exchange membrane with good chemical stability, proton conductivity and gas separation as solid electrolyte, which can effectively prevent electron transfer and improve the safety of electrolyzer. The main components of the PEM water electrolyzer are proton exchange membrane, cathode and anode catalyst layers, cathode and anode gas diffusion layers, cathode and anode end plates, etc. from inside to outside. Among them, the diffusion layer, catalytic layer and proton exchange membrane constitute the membrane electrode, which is the main place for material transport and electrochemical reaction in the entire water electrolyzer. The characteristics and structure of the membrane electrode directly affect the performance and life of the PEM water electrolyzer.